About MoonFibre

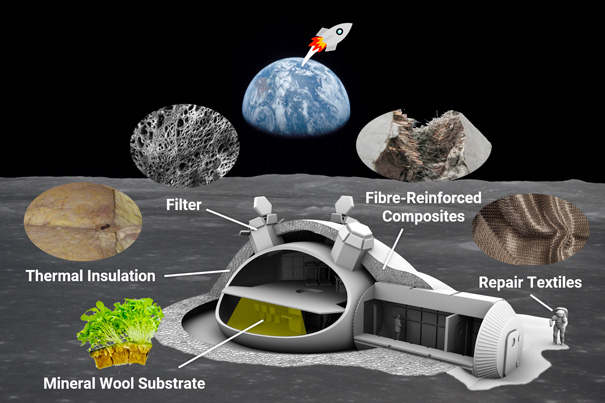

An in situ resource utilization technology aiming to produce fibres-based materials made of lunar regolith, directly on the Moon.

Jointly developed at RWTH Aachen University by the Institut für Textiltechnik and the Institute for Structural Mechanics and Lightweight Design.

Our mission is to reduce the cost and increase the sustainability of lunar settlements

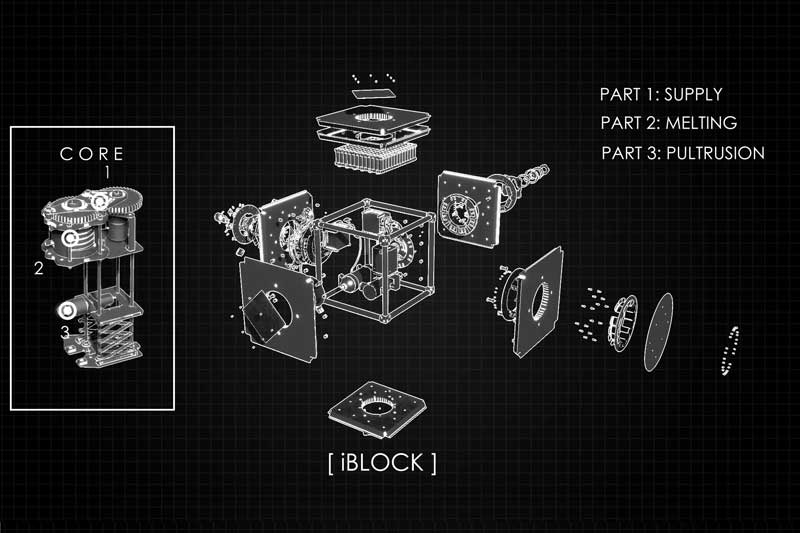

MoonFibre spinning unit can be operated under space conditions.

With the iBOSS satellite as payload element, the transport of the spinning unit is space qualified.